Mastering Permanent Lighting Power Injection: A Step-by-Step Guide

Table of Contents

- Introduction

- Understanding Power Injection

- Scenario 1: Basic Power Injection with a Power T

- Scenario 2: Power Injection with a Distant Power Supply

- Scenario 3: Power Injection for a Multi-Level Installation

- Scenario 4: Advanced Power Injection with Separate Controller and Power Supply

- FAQ

- Conclusion

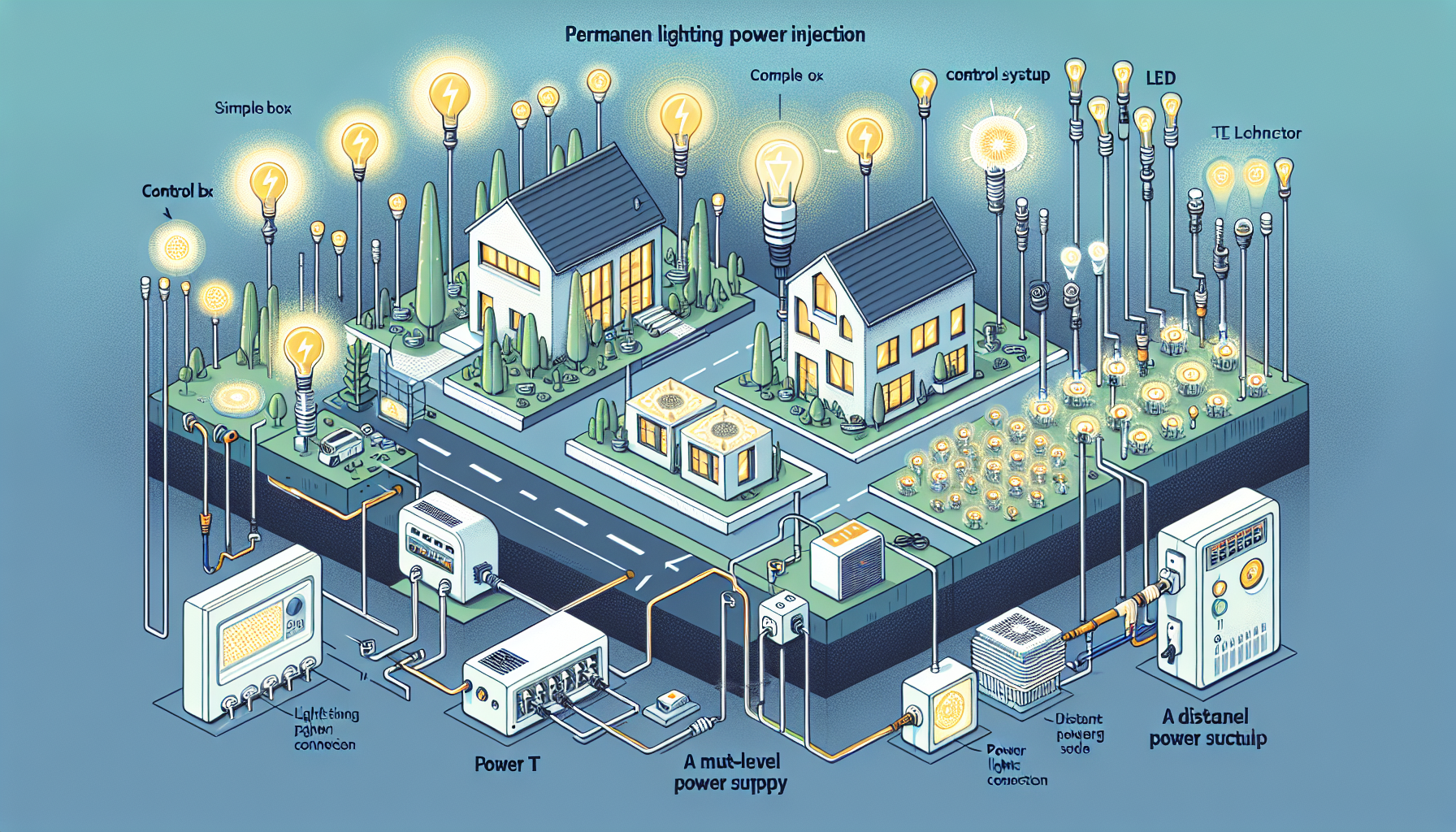

Introduction

Properly powering your Minleon Permanent Lighting setup is crucial for maintaining consistent brightness and reliability across your entire system. When installing more than 200 lights, power injection becomes a necessary step to ensure your lights function at their best. In this comprehensive guide, we'll walk you through the essential techniques for injecting power effectively, covering various scenarios to help you navigate your specific installation needs.

Understanding Power Injection

Power injection is the process of adding additional power sources to your lighting system to prevent voltage drops and ensure consistent illumination. This is typically required when the total number of lights exceeds the capacity of a single power supply. By strategically introducing power injection points, you can maintain optimal performance and avoid any dimming or inconsistencies in your lighting setup.

Scenario 1: Basic Power Injection with a Power T

The most straightforward method of power injection involves the use of a Power T. This T-shaped connector has two female connections and one male connection. The bottom female connection is where you'll directly inject power from a power supply. The signal will flow from left to right and right to left, but the power will only flow upward from the bottom female terminal.

In this scenario, you'll have a control box that sends the signal through the Power T. The power coming from the control box will be absorbed by the first 200 lights and spacer cable, leaving the Power T to serve as the injection point for additional power. By connecting a power supply to the bottom female terminal of the Power T, you can introduce the necessary power to energize the remaining lights in your system.

Scenario 2: Power Injection with a Distant Power Supply

Sometimes, the power supply may not be located near the 200-light mark, requiring a more complex power injection setup. In this scenario, you'll start with a Power T and a control box, but you won't utilize the bottom female terminal of the Power T. Instead, you'll cap it off and look for an outlet closer to the additional lights that need power.

To inject power, you'll use a basic T-connector, which will allow the power to flow both forward and backward. The power supply will be connected to the bottom of the basic T-connector, and the power will then be distributed to the remaining lights, up to a total of 250 feet.

Scenario 3: Power Injection for a Multi-Level Installation

In some cases, you may be dealing with a multi-level installation, such as a bi-level house, where the combined length of the upper and lower levels exceeds 250 feet. In this scenario, you'll need to split the signal and power between the two levels.

Start by adding a basic T-connector right after the control box, which will split the signal for the upper and lower levels. Then, connect a Power T directly to the basic T-connector for the lower level. By injecting power through the bottom female terminal of the Power T, you can power the entire lower level, while the upper level is powered by the control box.

This setup allows you to accommodate up to 400 to 500 lights across both the upper and lower levels, ensuring consistent illumination throughout the entire installation.

Scenario 4: Advanced Power Injection with Separate Controller and Power Supply

The most advanced power injection scenario involves separating the controller and power supply. In this case, you'll assume that the total length of the lighting system exceeds 200 feet, requiring a Power T for the initial power injection.

First, you'll draw the signal flow through the system, which is the simpler part of the setup. Then, you'll need to add power to the first section of 200 lights. You'll do this by injecting power through a basic T-connector from the power supply itself. This power will flow both directions, out to the Power T and into the controller.

To power the additional lights beyond the Power T, you'll need a second power supply. This power will flow from the bottom female terminal of the Power T and out the female terminal to the additional lights. You can repeat this injection process as many times as necessary, up to a total of 1,240 lights.

FAQ

What is the maximum number of lights that can be powered without requiring power injection?

Without power injection, you can power up to 200 lights with a 4.17 amp power supply or up to 250 lights with a 5 amp power supply, as long as the total combined length of the spacer cable and lights does not exceed 270 feet.

Can I use the bottom female terminal of the Power T for anything other than power injection?

No, the bottom female terminal of the Power T should only be used for power injection. It should never be used for any other purpose, as power will only flow in one direction - up from the bottom female terminal.

How do I determine the appropriate power supply amperage for my installation?

The power supply amperage required depends on the total number of lights in your installation. For up to 200 lights, a 4.17 amp power supply is recommended. For up to 250 lights, a 5 amp power supply should be used. If your installation exceeds 250 lights, you'll need to implement power injection techniques to ensure adequate power distribution.

Can I use the same power injection method for both the upper and lower levels of a multi-level installation?

Yes, the power injection method described in Scenario 3 can be applied to both the upper and lower levels of a multi-level installation. By using a basic T-connector to split the signal and a Power T for power injection on the lower level, you can accommodate up to 400 to 500 lights across the entire system.

How do I determine the optimal placement of power injection points?

The placement of power injection points will depend on the total length of your lighting system and the location of available power outlets. As a general rule, you should aim to inject power at approximately 200-250 foot intervals to maintain consistent voltage and brightness across your installation.

Conclusion

Mastering power injection is a crucial step in ensuring the long-term reliability and performance of your Minleon Permanent Lighting setup. By understanding the various scenarios and techniques outlined in this guide, you'll be well-equipped to tackle power injection challenges and create a seamless, energy-efficient lighting system that will shine brightly for years to come.